Model: XFS-150

Description

The automatic horizontal form fill seal machine is widely used in the packing fields of food, pharmaceuticals, house chemicals, cosmetics, etc. And our packing equipment is suitable for powdery, granular and liquid products. Three-side or four-side seal of pouch is available with kinds of blanking devices to packing different materials.

Application

The horizontal packing equipment is used for powdery and granular products: milk powder, protein powder, coffee powder, baking powder, granule sugar, glucose, MSG, juice powder, granular and powder additive, granule medicine, talcum powder, dyes, spices, veterinary drugs, pesticides, detergent powder, etc. Liquid and pasty products: tomato paste, fruit jam, shampoo, liquid fertilizer, pesticides, etc.

Features

1. The automatic horizontal form fill seal machine is controlled by PLC with human-machine interface display, which is easy to operate.

2. All the actions are driven by air cylinder, which improve machine’s efficiency, applicability and stability.

3. Horizontal packing equipment is the ideal choice for packing foodstuff, pharmaceutical, cosmetic, pesticide, and feedstuff industry.

4. Servomotor control system is available for going down film, so that we can adjust dimension of film randomly.

5. With the high sealing strength and firm package, there are never the ragged edges.

Technical Parameter

Model

|

XFS-150 Automatic Horizontal Form Fill Seal Machine

|

Machine dimensions

|

2850 × 970 × 1500(L × W × H) mm

|

Weight

|

900 kg

|

Electric supply

|

AC380V 50Hz

|

Power

|

3.5 kW

|

Air supply

|

0.5MPa

|

Air consumption

|

100NL/min

|

Packaging capacity

|

40 to 80ppm

|

Width of horizontal packing equipment

|

60mm to 140 mm

|

Length

|

80mm to180 mm

|

Max. filling capacity

|

160 ml

|

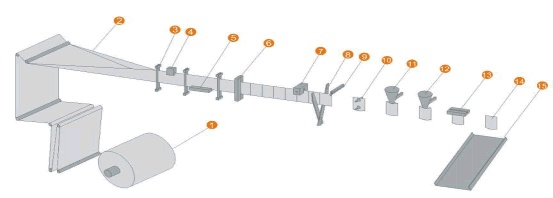

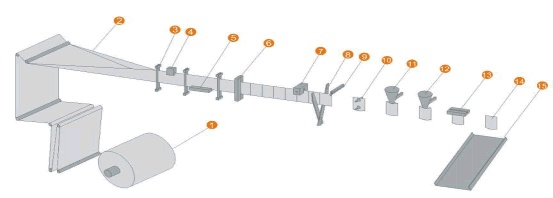

Packing Process of Automatic Horizontal Form Fill Seal Machine

1. Film unwind

|

4. Color scale detection

|

7. Tear notch

|

10. Pouch opening

|

13. Top seal

|

2. Film forming

|

5. Bottom seal

|

8. Cutting

|

11. FillingⅠ

|

14. Finished product

|

3. Film guide

|

6. Vertical seal

|

9. Pouch pulling

|

12. FillingⅡ

|

15. Outlet

|