Twin-sachet Powder Packaging Machine

Description

Twinsachet powder packaging machine adopts full stainless steel configuration with vacuum feeding device and servo screw device. The machine uses concise duplex output design. The max speed can up to160 bags/min. It is economic solution for high speed packaging for small bag.

Application

Twin-sachet powder packaging equipment is a kind of horizontal packing equipment, which is suitable for twin-sachet in high capacity. With auger filling system, it can pack powder material, such as health food powder, milk powder, coffee powder, Chinese herb powder, chemical powder, and drink powder in the industries of foodstuff, pharmacy and medicine.

Features

1. With the high sealing strength and firm package, there are never the ragged edges. It is the ideal choice for packing foodstuff, pharmaceutical, cosmetic, pesticide, and feedstuff industry.

2 In packaging design, the twin-sachet powder packaging machine has upright and elegant appearance without liquid, powder around the end seal.

3 All the actions are driven by air cylinder, which improve machine’s efficiency, applicability and stability.

4. Servomotor control system is available for going down film, so that we can adjust dimension of film randomly.

5. The horizontal packing equipment is controlled by PLC with human-machine interface display, which is easy to operate.

Technical Parameter of Twin-sachet Powder Packaging Machine

Machine dimensions

|

3500 × 970 × 1500(L × W × H) mm

|

Weight

|

1500kg

|

Electric supply

|

AC380V, 50Hz

|

Power

|

4.5kW

|

Air supply

|

0.5MPa

|

Air consumption

|

200NL/min

|

Packaging capacity

|

120 to 180ppm

|

Wide size

|

50 mm to 90 mm

|

High size

|

80 mm to 180 mm

|

Max. filling capacity

|

100ml

|

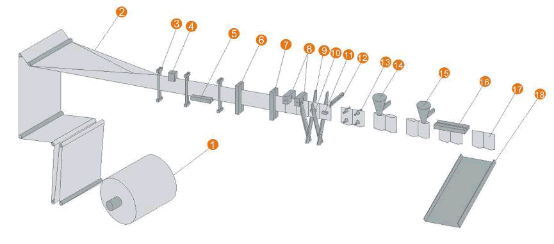

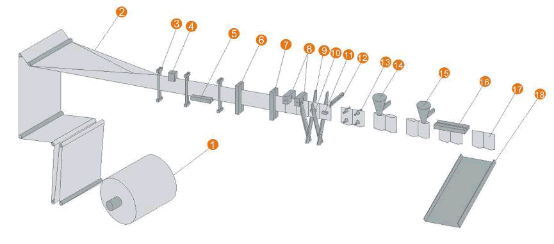

Packing Process of Horizontal Packing Equipment

1. Film unwind

|

4. Color scale detection

|

7.Vertical sealⅡ

|

10. Pouch clamp Ⅰ

|

13. Double pouch opening

|

16.Top seal

|

2. Bag forming

|

5.Bottom seal

|

8. Tear notch

|

11. Pouch clampⅡ

|

14. FillingⅠ

|

17.Finished product

|

3. Film guide

|

6.Vertical sealⅠ

|

9.Double cutting

|

12.Pouch pulling

|

15. FillingⅡ

|

18. Outlet

|